Kawasaki KH400 restoration

By

Mal King,

Bandicoot Trailers

By

Mal King,

Bandicoot Trailers

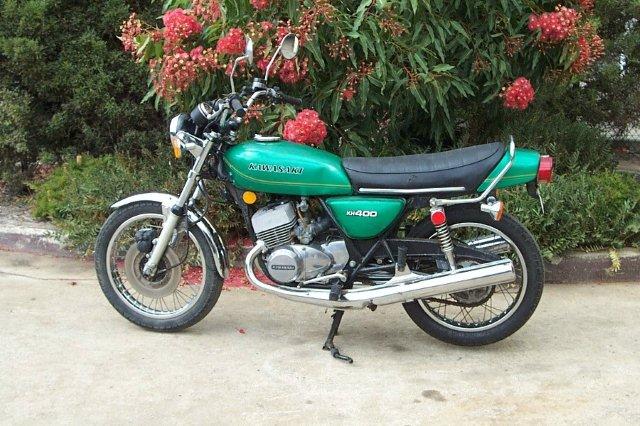

In 2009 I purchased a Kawasaki S2 350cc triple. Not long after, while skimming through a Bike Trader magazine at the local newsagent (as you do) , I happened upon an ad for another Kawasaki two stroke triple. This one was the later KH400, supposedly a much nicer bike to ride than the S2. I expect you know what happened next.

Don’t they always look good in the photos!

The bike was advertised as ‘restore or clean up and ride as is’. After seeing a couple of photos I had the bike shipped up from Victoria. Don’t they always look nicer in the photos. On first inspection I found a broken throttle cable, completely gummed up carburettors and the brake fluid had turned into a crumbling solid. It had all the signs of a bike that had been parked outside in the Californian sun for a very long time, as of course had been the case. The bike, however, kicked over with good compression, just as the man had said.

Decisions

and a bit of a rant

Decisions

and a bit of a rant

So the decision to restore the bike was made there and

then. An engineering background and some admitted love/hate relationships

working on mostly Italian bikes further boosted morale.

I remember one particular Italian bike where it was necessary to remove

the swing arm to be able to drop the battery out to top up the fluid.

Give me a break! The manual advised lifting out the battery from above;

pity about the frame strengthening gusset running across the top. I took

the opportunity to cut an inspection aperture in the said gusset.

Handling remained just as crisp by the way. Surely the Kawasaki wouldn’t

have any similar tricks up its sleeve? It did put up a bit of a fight as

I tried to remove the air box and battery carrier, but otherwise was

straightforward enough to work on.

Words of wisdom

A good basis for a rebuild is all rather obvious really:

buy the best condition bike you can afford with as much of the

original kit intact. For example to replace the exhaust system

on a triple is going to be very expensive, that’s if you can find one. If

you fit after market pipes you have all but destroyed the originality and

character of the bike.

The start

Not generally known for my patience, I surprised myself

by taking lots of detailed photographs BEFORE the strip down. I also had

a similar bike for reference, so although it was my first resto I felt

reasonably confident I could see the job through.

I parked the bike in an out of the way corner to start the strip down. I

had already decided to be quite methodical in my approach, again

surprising myself and buying a stack of storage bins and a large note

book. I took a photograph of every part as it was removed and logged down

in the book every screw type, length, head type, plain washer under head

etc, etc. I then stored the part in a relevant bin ready for the next

stage, a good clean up, replate, replace, that sort of thing.

No turning back

I stripped the bike down in what seemed a logical order,

remove tank, side panels and tail unit. With the paintwork out of the way

I removed the wiring loom, taking note of the various cable runs

especially, which way the main loom wraps around the frame. I got that

wrong in one place on the rebuild, it took a good while to correct. I

then removed the ancillary parts and remembered struggling to remove the

air box and battery carrier. Bit of a catch 22 really. Needed to remove

the air box to get to the battery carrier, but needed to remove the

battery carrier...

A mate helped to lift the engine from the frame as per workshop manual. A

milk crate came in useful to support the engine. It is a good idea to

have a storage place in mind first, especially so with a heavier engine;

the triple engine luckily is quite light. Remove wheels, drive out swing

arm bolt, remove fork stanchions and yokes, you're done.

It is a good idea at this stage to sit down and have a cup of tea (being

a pom) or a beer, to consider the next stage. The big thing that kept

coming back at me was to work in a methodical manner, take your time and

try to enjoy it. It's easy just to pull a bike to pieces and leave a pile

of oily bits on the floor! I separated all the parts into storage bins,

powder coat, replate, restore and so on.

A sense of order

I prepared the parts for the various refinishing

processes based on lead times, chrome plating seems to take a while,

powder coating seems to happen quite quickly. Not having any trade

contacts I went purely on recommendations on which people to use. Club

membership comes in handy at this stage, especially if like me you are

new to an area.

More decisions and oh dear

It is worth mentioning I chose powder coating for the

frame and some ancillary parts based on cost and durability. I know a lot

of folks prefer a more original paint finish.

I had decided not to be too precious over originality and went for a

durable finish and what I thought some useful upgrades on the rebuild.

You certainly learn were the factory cut costs and what can easily be

improved upon with modern processes and parts on a project like this.

Overall, I did not stray far from the original and just went for tapered

head race bearings, braided brake lines, more modern radial appearance

tyres, stainless wheel steel spokes, you get the idea.

Back to powder coating. You need to be prepared to take some time in

identifying areas that do not need powder coating, as it is quite a thick

coat and very hard, read hard to remove. (There are books written on the

subject). Likewise be prepared to clean out threads and earthing points

on getting the powder coated parts back.

In my particular case I spent some time talking to the powder coater,

himself a biker and used to coating bike projects. He assured me he would

mask ALL relevant parts with the special high temp tape. I have to say in

spite of this when I received the parts back, although an excellent job,

i.e. nice and shiny, uniform finish, this also included INSIDE the fork

stanchions and master cylinder. I was very lucky to find a specialist who

could remove this, AT a price of course, please be warned.

Getting into it now

With all the various parts listed (I kept copies for my

own reference) and sent off to the specialists for refinishing it was

time to take stock and make out yet another list of parts that were

beyond redemption or missing for replacement. Where ever possible I tried

to obtain NOS (new old stock parts.) This is when you are pleased you

chose a model with good vintage spares back up. I went through a learning

curve but am pretty sure I know most of the main players in the supply of

vintage Kawasaki parts, both new and used. Amazing how much new old stock

is still listed and available from Kawasaki themselves by the way.

More work but worth doing

It is probably worth mentioning at this time that I

cleaned the parts as best I could before sending off for refinishing. Not

too many people want their chroming vats contaminated with two stroke

exhausts, they will also charge accordingly for any pre-treatments.

Cleaning the parts I could reuse

Time to get mucky again; old clothes and plenty of

degreaser. I used a plastic washing up bowl set up at camping stool

height to save grovelling on the deck, or more correctly to obtain a

useful working height. A pair of glasses for eye protection, rubber

gloves ditto for hands and got stuck in. I did most of this outside in

the Queensland sunshine.

I

started off cleaning the control cables, for no particular reason other

than you have to start somewhere. These came up remarkably well, as did

the wiring loom. I hung all these up (vertically) on nails tapped into

the woodwork around the garage. This kept them out of the way and took up

the least amount of room and I was able to run some lubricating oil

through the cables as well. I could then put a tick against these as

ready for re-assembly.

I

started off cleaning the control cables, for no particular reason other

than you have to start somewhere. These came up remarkably well, as did

the wiring loom. I hung all these up (vertically) on nails tapped into

the woodwork around the garage. This kept them out of the way and took up

the least amount of room and I was able to run some lubricating oil

through the cables as well. I could then put a tick against these as

ready for re-assembly.

As I went through the pile of parts I started to continue the theme and

hung as many parts up on the garage walls as I could. Other parts I

simply placed into a rack of storage bins.

With everything cleaned up as best I could I decided to repaint certain

parts. This included the metal ferrules on the ends of the control cables.

The end result was pleasing and saved a few dollars, well quite a few

actually on buying new cables. I even managed to get the broken throttle

inner cable repaired. Actually a new cable would have been cheaper!

New nuts & bolts

With all the bits of bike either away at the finishers

or hanging on the garage walls or cleaned and repainted and waiting in

storage bins I had time to consider my next move.

I

chose to take my list of replacement nuts bolts and washers to the local

stockist. In my case everything was very sensibly (thanks Kawasaki) in

metric threads. Mostly metric ‘Coarse’ threads, but some metric ‘Fine’. I

chose to use “nyloc” self locking nuts in place of spring washers and

plain nuts were possible. Sometimes it works; sometimes the physical size

is too large. You just have to make a judgement call on what looks right.

I

chose to take my list of replacement nuts bolts and washers to the local

stockist. In my case everything was very sensibly (thanks Kawasaki) in

metric threads. Mostly metric ‘Coarse’ threads, but some metric ‘Fine’. I

chose to use “nyloc” self locking nuts in place of spring washers and

plain nuts were possible. Sometimes it works; sometimes the physical size

is too large. You just have to make a judgement call on what looks right.

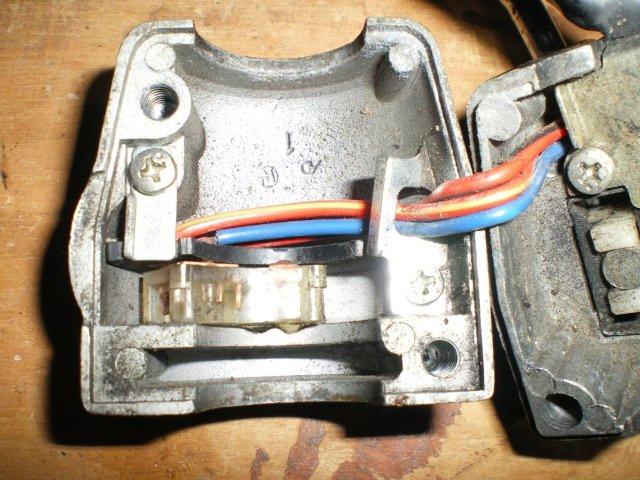

Switch gear

I chose this time to have a look inside the switchgear housings. More digital pics and a spot of penetrating goo on the various fixings. I found it best to really take my time and not rush this part especially. The fixing are quite small M2 and M2.5. I also took note of the various insulating washers under the heads of some screws. I took the precaution of laying out a large piece of rag to work on just in case any of the small parts tried to go AWOL.

After a good clean up and check of all the various conducting surfaces it

was time for careful re-assembly. In my particular case I had sent off

the switch housings with the rest of the parts for powder coating. Of

course when these parts come back all the markings are powder coated over

too. I spent a good while with an artist’s brush and pots of white and

yellow enamel refilling the original engravings.

After a good clean up and check of all the various conducting surfaces it

was time for careful re-assembly. In my particular case I had sent off

the switch housings with the rest of the parts for powder coating. Of

course when these parts come back all the markings are powder coated over

too. I spent a good while with an artist’s brush and pots of white and

yellow enamel refilling the original engravings.

More decisions and send bits off

Well, I seemed to be getting on okay. More mental notes…

Note 1: engine still sits on milk crate. Did I order a gasket set? Note

2: Speedo and rev counter dials faded by years of sunlight. Order new

dial faces as this can badly upset the overall effect of any restoration,

have seen it many times. Bike looks like new; the dials really shout back

at you, I’m at least thirty years old. Note 3: Same goes for paintwork,

tank side panels and tailpiece all faded paint. Choose colour and order

correct decal set. Have I forgotten anything? Well of course I have; just

won’t find out what till later!

Double check

Double check

What to do next? Made sure all the parts I needed were

on order: check. All parts for refinishing out there: check. All other

parts, cleaned, repainted and ready to go back on the bike: check.

Engine & Carburettors

Right, it was then time to have a look-see at the motor.

I had prised out the rubber engine mounts earlier and although they

appeared to be in very good condition I would have replaced them as a

matter of course, but was unable to source any new ones. So I lubed the

old ones with “just like new” rubber enhancer ready for reassemble.

The motor appeared in good condition externally so I just blocked off the

important little places and gave it a degrease and hose down. Next I

removed the carburettors. They were completely gummed up but easily

stripped and cleaned with the help of some proprietary carb cleaner and a

good brush for the outside castings.

The engine had good compression so I limited the work to just removing

the cylinder heads for a check inside. The engine internals looked to be

in excellent condition with no lip on the barrels etc. and generally very

clean. This is an advantage with buying a bike with low verified miles I

guess, shouldn’t be too much wear and tear. The heads I masked up and

took to a local shop for a very light sand blast.

I replaced the heads, happy that I had ordered the new gasket set and

masked and sprayed the barrel and heads with high temp aluminium finish

paint. Once I had hand polished the engine casings I was quite satisfied

with the overall effect. Replaced the carbs and called it job done.

It

may sound odd but I was not overly worried about the engine. I just

treated it as a unit I can work on “if necessary” another time.

It

may sound odd but I was not overly worried about the engine. I just

treated it as a unit I can work on “if necessary” another time.

My rationale for this went something along these lines. As long as these

Kawasaki two strokes have compression and a spark it is hard for them not

to go. They are of a very simple, read easy to work on, piston port

design. They are also very robust. If you do need spares they are cheap

and plentiful. Oh and the sound of a two stroke triple is like no other!

I knew now that I could remove the engine unit in around twenty minutes.

If ever I do need to then that is the time I will get the engine bead

blasted and refinished professionally.

On the home straight

Next was the good part, as all the new and refinished parts started to arrive. I spent the best part of a day checking that I had all the parts back from the powder coaters and started to clear all the threads, earthing points and the like for unwanted powder coat. It was quite difficult to remove some of the baked on masking material. But the job got done; they really had done an excellent job. I just had one piece missing which they could not find. So I found a local machinist to make up a new chain adjuster block from the pattern I already had. Although only a small cost in itself, they do all start to add up.

Thought things were going too well!

Rather more disappointing was the powder coat on the

inside of the fork stanchions and brake master cylinder. I count myself

fortunate to have found somebody skilled enough and with the right

equipment to hone the parts clear of powder coat. Now what was I saying

about all the small costs adding up? I had the forks and brake calliper

rebuilt by the same people so I got them back all ready to fit on the

bike, which was nice.

The rebuild

The rebuild

I started the rebuild proper by first fitting the swing arm; I had already pressed in the new steel bushes. Armed with digital photos I carefully inserted the freshly greased swing arm bolt from the correct side and slid on the plain washer and new nyloc nut. I did not fully tighten anything fully at this stage, but just “nipped” things up.

So that’s what it looked like

Same process to fit the steering stem with the new

tapered bearings, followed by the fork legs themselves. Now seemed like

the right time to fit the wheels back into the frame. It started to look

like a bike now. I really was taking my time now and making sure

everything went back correctly and easily without using undue force on

anything.

Next I fitted the battery holder and air box followed by the rear wheel

guard. I decided to fit the engine back in at this stage. I placed all

the lightly greased engine bolts out in order, and laid some rag on the

frame to look after the fresh powder coat. A mate helped me offer the

engine up into the frame while my wife slipped in a couple of engine

bolts. It really was that easy with the light weight of the Kawasaki

engine. I tightened everything to the correct torque with the steering

head bearings adjusted in the time-honoured fashion.

Easily done?

After fitting the headlight shell it was time to

install the wiring loom. I just loosely cable tied it in place at this

stage. I did manage to get it the wrong way round one of the frame tubes,

even with the photos. Save to say I got a bit angry with myself at this

point as it took quite a while to feed it back through without straining

the cabling. I was determined not to do any disassembling at this stage,

so struggled on.

Now it was just a case of fitting all the rest of the ancillary

components back in a rational order, so I will not labour this stage.

Once everything was back in the right places I fully connected the wiring

loom and tensioned the securing cable ties.

It really did look like a Kawasaki now. I connected up all the control

cables and checked the cable runs and roughly adjusted the carburettors

and clutch while still easy to get to.

Happy days

On the home run now. Time to bolt on the newly chromed

exhaust system. How good did that look? All I needed now was the new

paintwork.

This got a bit frustrating, as I still had to wait another few weeks

although I had got it to the painter in plenty of time. I eventually got

it back and what a superb job, I just could not fault it. A couple of

hours later it was on the bike and I fitted the original Californian

number plate to complete the job.

.jpg)

.jpg)

.jpg)

Devil’s in the detail

Of course it was not really finished as I had to check

all the fixings were tightened up to the correct torque, all the circlips,

clips etc. were all fitted correctly, adjusted drive chain and rear brake

and so on and probably lots more things to discover still needed some TLC.

As I was lucky enough to have another triple to ride I decided to leave

this one in a dry stored state for a while at least, so resisted the

temptation to add fuel and oil and swing on the kick-start.

Just in case I’ve made it all sound like plain sailing I can assure you I

had the customary grazed knuckles and several temper tantrums, dummy

spits and “is it all worth its” along the way. Also I had some amusing

moments when you just have to laugh at yourself for being so stupid.

Overall though, it was immensely satisfying.

Time to contemplate

Has it all been worth while? In pure dollar terms

probably not. But if you want one of these bikes in restored condition,

you just have to bite the bullet. I can see why the professional

restorers’ prices may seem so high; they have to take into account their

time, I didn’t.

I have listed most of my costs but inevitably some get by you, as does

all the running around incurred along the way. However I do have actual

costs rather than some of the folklore you may hear from time to time.

In terms of keeping a little bit of two stroke triple history going it

was most definitely worthwhile. I have to say that if I had been waiting

on this bike to be finished so I had something to ride it would have NOT

been half as enjoyable as it turned out to be.

Keep it upright (especially after all that work)

Mal